NEWS / ARTICLES / CASE STUDIES

Rail Car Repair Solutions

Whiting Corporation is your trusted partner for comprehensive rail car repair services and mobile railcar repair solutions. We provide high-quality,…

Choosing the Right Railway Lifting Equipment

You can count on Whiting Corporation to be your premier supplier for the highest quality railway lifting equipment and railcar…

Improving Rail Transport Operations & Downtime

Whiting Corporation is your trusted partner for comprehensive lifting equipment for rail transport operations and freight operations. This article delves…

Welcome to 2022 – the year everything gets back on ‘track’!

Welcome to 2022 – the year everything gets back on ‘track’! As ridership increases back to normal levels, we’ve heard…

Custom Heavy-Duty AGV OEM for Your Manufacturing Needs

Does your assembly plant create large equipment for major industry? Are you looking to automate your processes but concerned over…

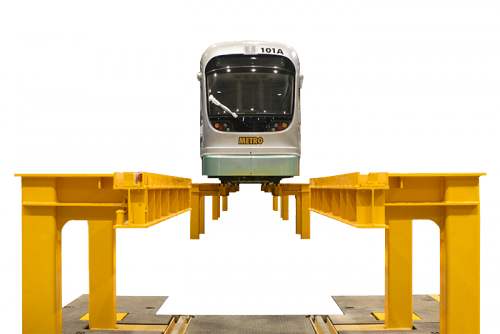

Whiting Car Hoists Keep Valley Metro’s Rapidly Growing Light Rail System On Track

The Valley Metro light rail system provides public transportation for central and downtown Phoenix, as well as areas of Tempe, and uses state-of-the art light rail vehicles, offering passengers a frequent and reliable service.

To ensure this reliable service is continued during the maintenance and repair operations of the ultra-modern rail cars, Whiting car hoists have been installed in the rail system’s Operations and Maintenance Center.

Whiting Sponsors High Speed Rail Alliance Luncheon

Whiting Corporation was excited to be one of the executive sponsors of the High Speed Rail Alliance (HSRA) Spring Luncheon…

We Look Forward to Seeing You at ASLRRA’s 2024 Conference!

We look forward to seeing you at ASLRRA’s 2024 Annual Conference & Exhibition March 24-26 at the Kansas City Convention…

Whiting Kicks Off 2024 at NRC Conference & Exhibition

2024 is off to a fantastic start because we were able to connect with so many of you last week…

Year End Best Practices

As we end 2023, let’s reflect on our successes and identify where we can make improvements for 2024. Your rail…

Whiting Connects at APTA Expo

Today is the last day of the American Public Transportation Association‘s APTA Expo! We have loved meeting with so many…

Rail Shop Equipment Reliability Program

Your Rail Maintenance Equipment serves a vital role in maintaining the operational efficiency of your rail cars and locomotives. The…

Whiting Single-Truck Turntables

Whiting Single-Truck Turntables utilize a center mounted rotek-type bearing for their reliability and ease of use.

Whiting turntables are extremely rugged, well-balanced, and are suitable for the heavy demands of transit and freight maintenance shops.

Using the telescopic handle, the manual turntable is easy to rotate, and with the rails aligned, the handle locks into place and collapses out of sight.

Single-truck turntables are able to rotate the truck in 90 degree increments making it critical for moving trucks between the car service track and truck repair hoists in modern maintenance shops.

Whiting can custom-engineer a manual or motorized turntable in any configuration, size or capacity to suit your exact specifications.

With minimal routine maintenance needed, Whiting turntables are known for their long term reliability and safety in maintenance shops across North America.

Whiting Corporation Elevates American Transit.

Whiting Truck Repair Hoists

Whiting’s truck repair hoists range in size from 9-22 Tons, and are an integral part of the car hoist maintenance system in many modern transit and freight maintenance shops.

A truck repair hoist’s primary purpose is to increase shop safety and efficiency by providing maintenance personnel with a convenient access height for the inspection, maintenance and repair of the truck.

Using a rugged and proven electro-mechanical steel-alloy screw and bronze-alloy nut design, the two-screw Truck Repair hoists offers self-locking nuts along with steel safety nuts as backup for added failsafe protection.

Added features like over travel limit switches help make the Truck Repair Hoists one of the safest pieces of equipment in your maintenance shop.

With minimal needed routine maintenance, Whiting Truck Repair Hoists are known for their long-term reliability, open design for easy truck servicing and safety in maintenance shops across North America.