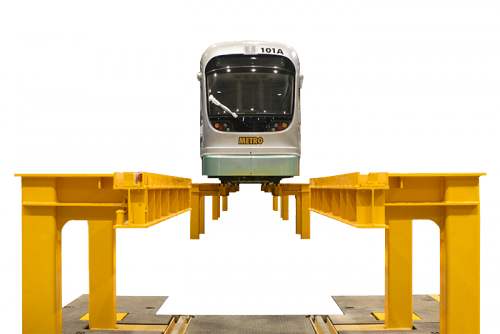

Car Hoist Systems – Safe Lifting of Multiple Transit Cars

Discover the pinnacle of safety and efficiency in railcar underbody and side component repairs with Whiting car hoist systems. Our patented safety design sets us apart, ensuring a secure and controlled lift, minimizing the risk of incidents associated with sudden drops. Explore the innovative features of our car hoist systems, including electromechanical screw and nut designs, articulated capabilities, and customizable configurations to meet your specific site requirements.

Whiting Car Hoist Systems:

Patented Safety Design: Whiting car hoist systems are equipped with a patented safety design that prioritizes controlled lifting, significantly reducing the potential for sudden drops. Trust in our commitment to safety during railcar repairs.

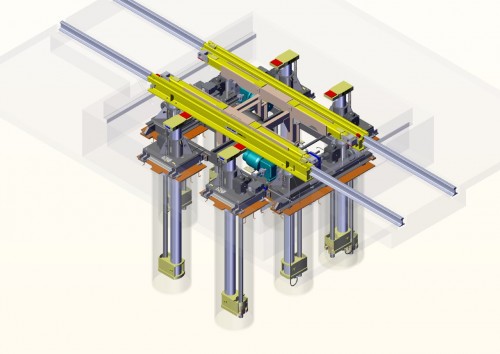

Versatile Lifting Options: With time-tested mechanical screw and nut designs, our car hoist systems offer versatility in lifting entire transit cars. Choose from two or four screw designs with standard capacity ranges up to 50 tons. Lift cars individually, in pairs, or articulated to meet the unique demands of your railcar maintenance tasks.

Custom Engineered Solutions: Tailor Whiting car hoists to your site’s specific needs with custom engineering for deep or shallow pit configurations. Our flexibility ensures that your railcar repair facility is optimized for seamless operations.

Inadvertent Lowering Prevention: The electromechanical screw and nut design of our car hoist systems require motor power for both raising and lowering, minimizing the risk of inadvertent lowering with personnel in proximity. Safety is paramount, and our design reflects that commitment.

Body Hoists and Supports:

Screw-Driven Precision: Integral to our Car Hoist System are body hoists and supports, employing a screw-driven mechanism. Lift your railcar bodies with precision, utilizing lifting pads that make contact with jacking points for secure and controlled elevation.

Versatile Applications: Our body hoists and supports seamlessly integrate with car hoists, providing options for body and truck separation or elevating bodies to convenient heights for under-car inspection and repair. Standard capacities range from 5 to 20 tons, offering flexibility for various railcar maintenance tasks.

Choose Whiting for railcar repairs that prioritize safety, efficiency, and precision. Our car hoist systems, equipped with patented safety features and versatile designs, along with body hoists and supports, ensure a seamless and secure lifting experience. Elevate your railcar maintenance operations with Whiting’s commitment to innovation and safety.

Examples of Whiting Car Hoist Systems

Installation / repair services and OEM replacement parts are also available from Whiting. Contact us today for more info or a quote!