Drop Table Pioneers

At Whiting, we take immense pride in pioneering the revolutionary drop table concept, transforming the landscape of wheel set change-outs in the railcar maintenance industry. Opting for a Whiting drop table guarantees not only swiftness but an unparalleled level of ease and efficiency, making it the undisputed choice for railcar maintenance professionals.

What sets Whiting apart is our commitment to a personalized approach. Our dedicated team of engineers takes the time to deeply understand your specific requirements, ensuring that the drop table system we create is not just a solution but a tailored masterpiece designed to seamlessly integrate with your unique application. With Whiting, you’re not just getting equipment; you’re getting a customized solution crafted for optimal performance in your distinct operational environment.

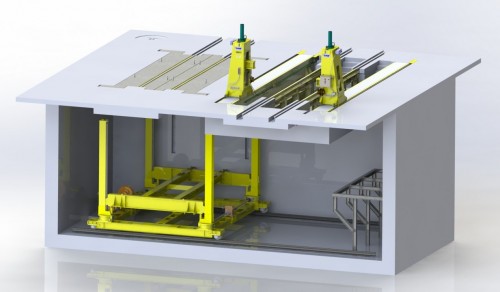

Among our stellar lineup of railcar maintenance equipment, the Full Truck Drop Table stands out as a testament to our dedication to reliability, safety, and ease of maintenance. Engineered to handle two and three-wheel axle trucks weighing up to 250 tons, the Full Truck Drop Table is a powerhouse in facilitating efficient wheel set change-outs.

The operational process with our Full Truck Drop Table is meticulously designed for maximum efficiency. As the locomotive is precisely positioned and supported over the table top, the trucks or wheels are seamlessly disconnected, lowered, transferred laterally, and then raised to a release track. This strategic sequence ensures a seamless transition, allowing the trucks to be effortlessly moved to a designated maintenance area for swift inspection and repair.

Choosing Whiting isn’t just a choice; it’s a commitment to excellence in railcar maintenance. Our Full Truck Drop Table not only streamlines the wheel set change-out process but also contributes to the overall efficiency of railcar maintenance operations. With Whiting, you’re not just investing in equipment; you’re investing in innovation, reliability, and a legacy of excellence in railcar maintenance solutions. Join us at Whiting, where we set the standard for industry-leading innovation and excellence.

Full Truck Drop Table Features

Body Supports and Girders

When removing drive wheel sets or trucks, the locomotive is located and supported over the table top, where the trucks or wheels are disconnected, lowered, transferred laterally and raised to a release track.

Operator Console

Whiting Drop Tables feature a remote operator console or a wireless pendant so the operator does not need to be close to the table during its operation.

Customized Capacity

Installations now operate in pits from 4 feet to 26 feet in width and in lifting capacities ranging from 20 to 125 tons.

Self-Locking Jack Screws

Whiting’s Drop Table design features self-locking jack screws that remain stationary in the event of a drive mechanism malfunction….regardless of the table load.

Release Track Top

Equipment installations can include a release track top which can be designed as a lift-off or bascule (split top) type.

Rugged Components

Features include splash lubricated gearing, sealed bearings, and self-locking screws and nuts.