MAC Jack

Revolutionize your railcar maintenance with Whiting’s Mobile Articulated Car Jack (MAC Jack), a hydraulic marvel designed for unparalleled efficiency and flexibility. Transforming wheel or truck change-outs into a swift operation, the MAC Jack sets a new industry standard by completing tasks in as little as 20 minutes.

Unmatched Performance:

- Versatile Lifting Capacity:

- Uniquely engineered to effortlessly lift unloaded well and center beam-type articulated railcars, reaching heights of over 30 inches above the rails.

- Handling Power:

- Capable of managing railcars in the yard weighing up to an impressive 50 tons, the hydraulic MAC Jack showcases exceptional strength and reliability.

Innovative Design:

- Low Profile Advantage:

- Requires only a 6” rail clearance without an adapter plate (8 ½” with an adapter plate), maximizing operational convenience.

- Hydraulic Flexibility:

- Featuring a hydraulic system with two lifting cylinders, one of which pivots to a horizontal position for easy undercar access, facilitating efficient maintenance tasks.

- Fail-Safe Mechanism:

- In the unlikely event of hydraulic system failure, a ratchet and pawl system come into play, ensuring a complete mechanical fail-safe condition for enhanced safety.

Operational Versatility:

- Self-Contained Power Unit:

- The heavy-duty MAC Jack comes equipped with a companion self-contained power unit, offering a seamless and self-sufficient solution for servicing railcars.

- Any Location Servicing:

- The MAC Jack’s versatility extends beyond expectation, enabling railcar servicing in any location where a fork truck can operate. This transformative capability turns your entire yard into a dynamic repair shop.

Time-Efficient Repairs:

- With the MAC Jack, time becomes your ally. Rapid wheel or truck change-outs, combined with the jack’s operational adaptability, significantly reduce downtime and enhance the overall efficiency of your railcar maintenance operations.

Reliability at Its Core:

- Whiting’s commitment to reliability is evident in the heavy-duty construction and innovative design of the MAC Jack. Every component is meticulously crafted to withstand the demands of railcar servicing, ensuring long-term performance and durability.

Embrace the future of railcar maintenance with the hydraulic MAC Jack from Whiting—an embodiment of efficiency, versatility, and reliability. Redefine your operational capabilities and experience unparalleled convenience in your railcar servicing endeavors.

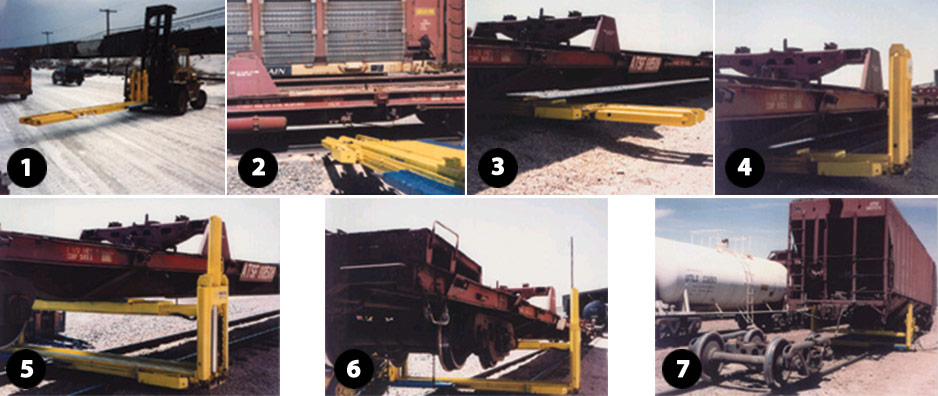

- Move MAC Jack across yard quickly with a fork truck

- Position jack under railcar with a min. clearance of 6”

- Slide unit under the railcar

- Pivot lifting cylinder back to a vertical position

- Activate unit to take weight off wheels

- Disconnect wheels and lift railcar

- Change out wheels