For decades, Whiting has been a trusted name for railcar lifting equipment for the transit and freight railroad industries. Whiting designs and manufactures systems to solve your maintenance problems.

That same quality and reliability that is synonymous with new Whiting equipment is also the cornerstone for Whiting replacement parts. Whiting Corporation is the only OEM provider for original parts. From portable electric jacks to drop tables, car hoists to turntables, Whiting is your source for quality components the way the equipment was originally designed.

Found in maintenance shops and rail yards across North America, the Whiting Portable Electric Jack is the industry standard that continues to outlast the competition. From jack screws, to brackets, to nuts, Whiting is the only OEM parts supplier for Whiting Portable Electric Jacks. With a variety of standard parts for your jack in stock, Whiting will work with you to get your jack quickly back in service.

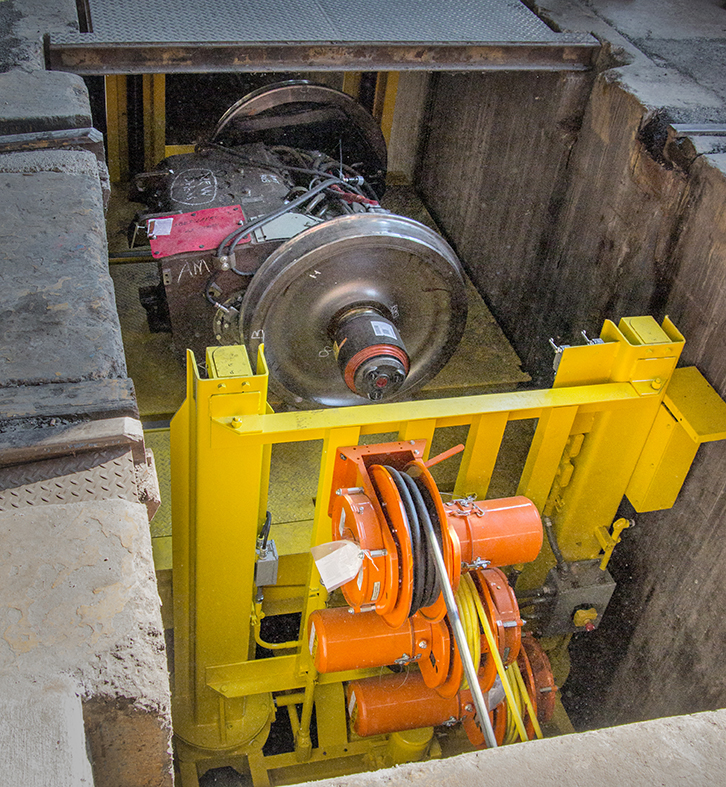

Drop Table and Body Supports Parts

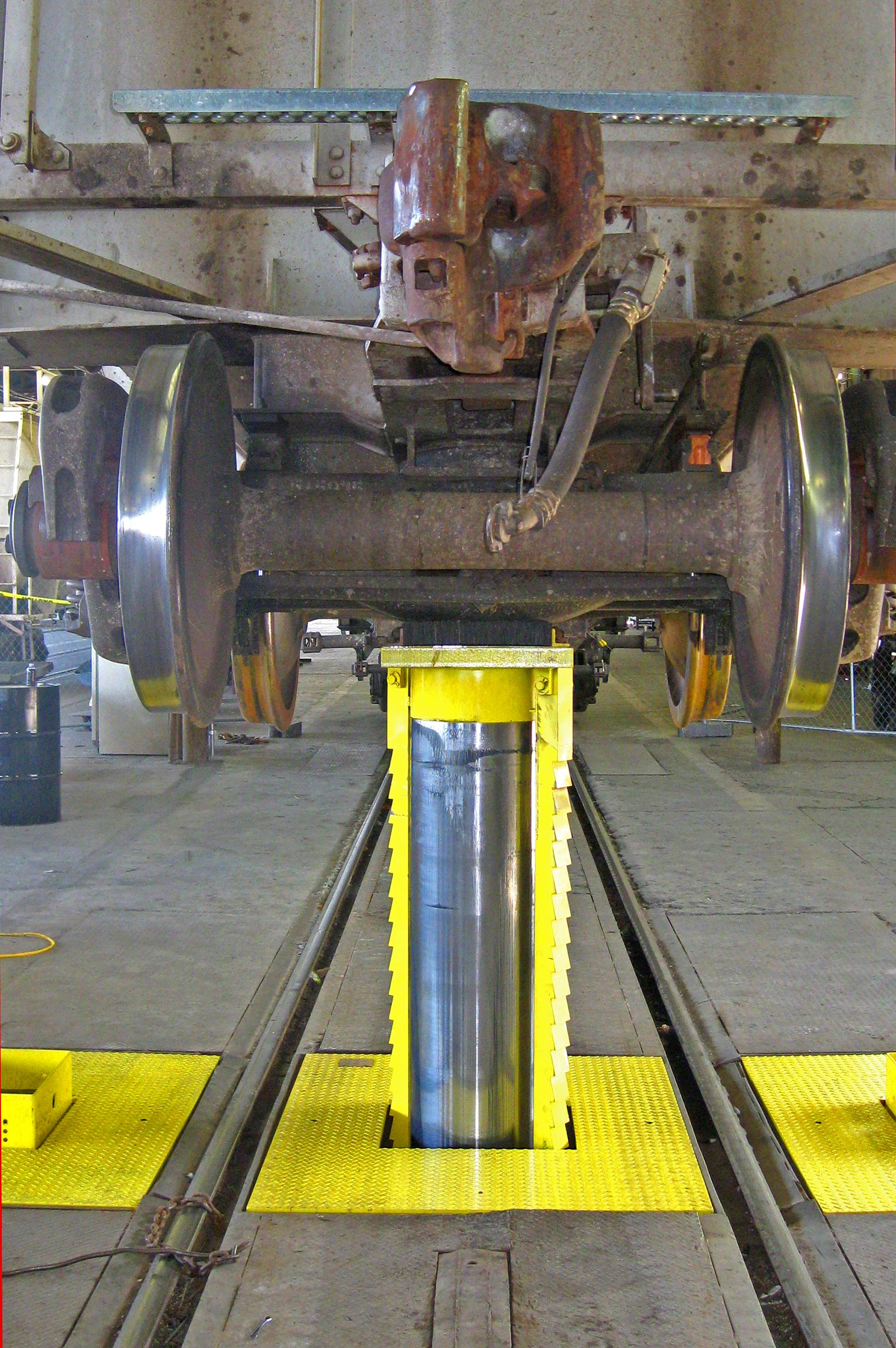

Whiting was a pioneer in the development of drop tables. Known for their reliable and safe operation, Drop Tables are available for either single axle or full truck removal. Wheel set change outs are quick, efficient, and cost effective because of Whiting’s time-tested designs. Whiting Full Truck and Single Axle Drop Tables are integral to the smooth operation of maintenance facilities. When removing full trucks, the locomotive is located and supported over the table top by body supports. Standard capacities range from 30 to 62½ tons. From a traction motor dolly to a screw assembly, you can count on Whiting to deliver this same performance in their replacement parts.

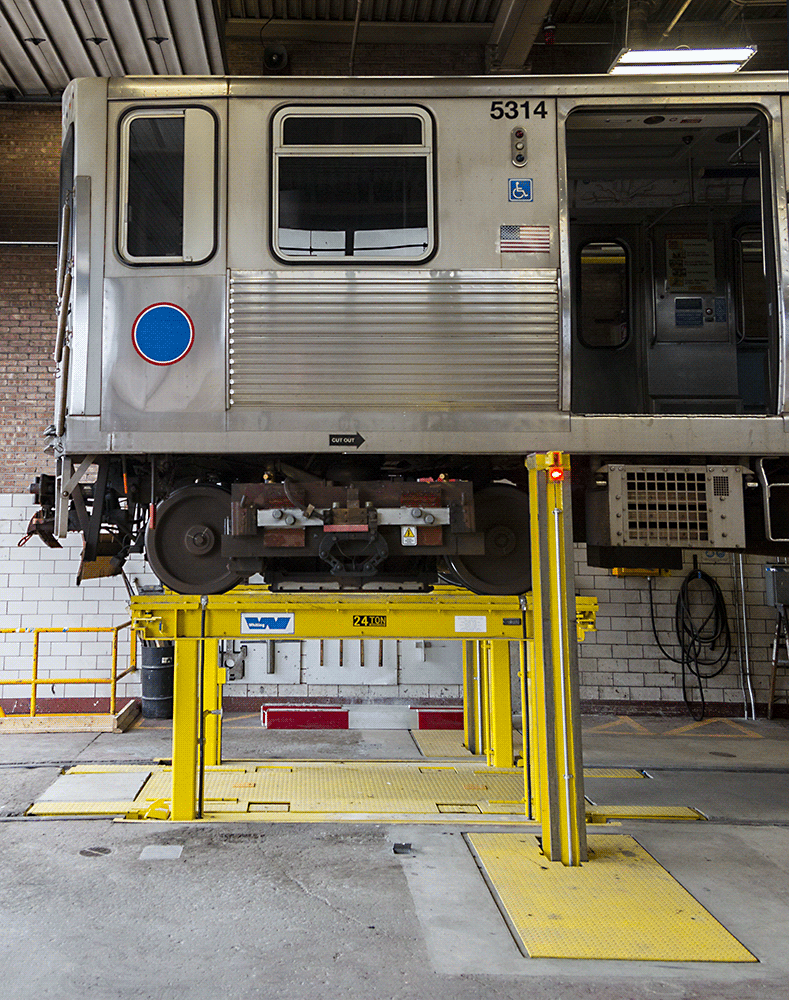

Whiting car hoist and body hoist systems work together to elevate the entire transit car to a convenient height for worker access to underbody and side components, as well as to facilitate bogie truck change outs. The body hoists can be used in conjunction with the car hoists to provide body and truck separation and easy change out of truck sets. Only Whiting car hoists utilize a patented safety design to raise and lower railcars that reduce the possibility of incidents caused by sudden dropping of the elevated car. Truck Repair Hoists also provide maintenance personnel with a convenient access height for the inspection, maintenance, and repair of the truck and bogie, and are known for their long-term reliability and open design for easy and safe truck servicing. With Whiting you can rest assured that replacement parts from the electromechanical screws and nuts to load limit sensors are manufactured according to the original part drawing.

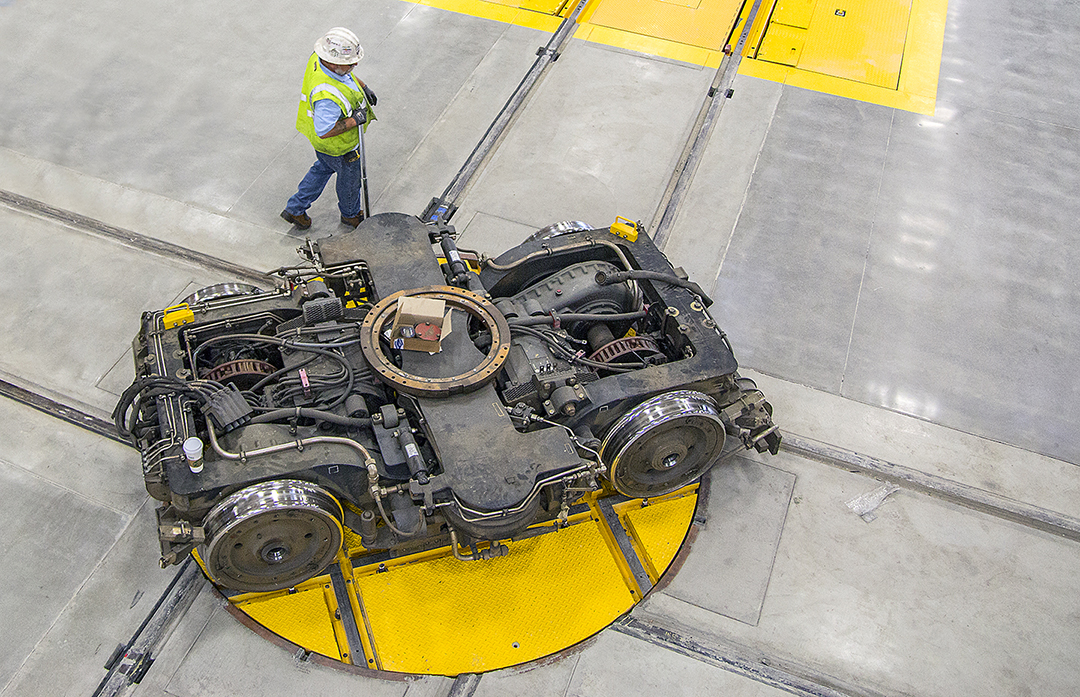

With minimal routine maintenance needed, Whiting turntables are known for their long-term reliability and safety. They are are custom-engineered and manufactured in different sizes based upon the application. Whiting turntables are extremely rugged, well-balanced, and are suitable for the heavy demands of transit and freight maintenance shops. Safety and quality are the foundation of all Whiting products, and that includes replacement parts.

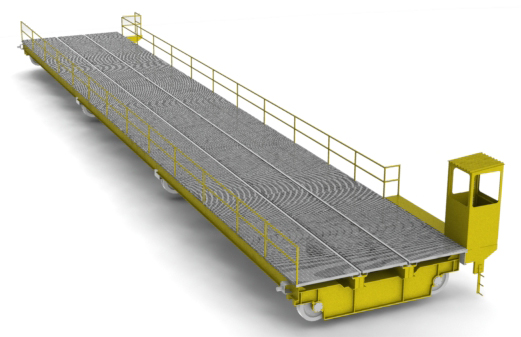

Transfer tables are an invaluable tool for maintaining traffic flow between tracks in your car repair or maintenance shop. While standard transfer tables normally require a pit up to several feet deep, Whiting can supply a table not requiring any pit at all. This design is most unique in that it still permits normal traffic flow on a track even when the transfer table is busy on another track.. Come to Whiting for all your OEM transfer table replacement parts from switches to motors to wheels and everything in between.

Whiting Repair In Place (RIP) Jacks raise a car off the track and facilitates access to the underbody of the car for repairs. They can be engineered and arranged to maximize efficiency of the lifting application at any repair facility. They support increased car utilization as the work flow in end of car operations, such as changing out draft gear, is now completed in a shorter time period. Whiting RIP Jacks feature a remote console so the operator does not need to be close to the freight car while the lift is in operation. Only Whiting offers OEM replacement parts for RIP Jacks. New RIP Jacks are manufactured by our hydraulics group.

Car Progression System Parts

Car Progression System Parts

Whiting car progression systems operate on a dedicated track and are used to progress one or many cars at a time along a maintenance line. These systems avoid many of the obvious hazards associated with the usual exposed tag line car pullers. Only Whiting has all your OEM replacement parts for your car progression system.

Whiting manufactured a variety of car-handling systems involving several combinations of remotely-controlled railcar movers, or pullers. Railcars are moved from the inbound storage area and indexed one at a time through the repair shop and onto the outbound storage track. Both double puller and single puller versions are available. Replacement OEM car puller parts provide the same quality performance whether it’s a coupling, magnetic brake, or rotary cam limit switch. New car pullers are available from our hydraulics group.

Whiting is the only supplier of genuine Whiting OEM replacement parts as manufactured according to the original part drawing.