Hydraulic Jack Programmable Logic Controller (PLC) Safety

Hydraulic Jack Programmable Logic Controller (PLC) Safety

Unlock unparalleled safety and operational excellence by transitioning your in-floor jack systems to the Whiting PLC Safety System. Our state-of-the-art upgrade is not just an enhancement; it’s a transformative solution designed to propel your lifting operations to new heights of efficiency, reliability, and, above all, safety.

Customized Precision:

Whiting engineers invest time and expertise to understand the intricacies of your unique applications. This dedication ensures a custom solution that seamlessly integrates with your specific requirements, offering a level of precision and adaptability that goes beyond industry standards.

Advanced Safety Features:

- Safety Dog Monitor:

- Continuously monitors the safety dog, providing real-time assurance of proper and secure operations.

- Automatic Pump Shut-off:

- Contributes to sustainability by intelligently saving energy and extending the operational life of the pump through automatic shutdown when not in use.

- End Jack Synchronization:

- Ensures synchronized movement of jacks under load, guaranteeing a smooth and uniform lifting experience.

- End Jack Drifting Down Under Load Detection:

- Swiftly identifies any downward motion of jacks, proactively preventing potential hazards and maintaining stability.

- Runaway Jack Condition:

- Responds instantly to a runaway jack condition by shutting off the pump, prioritizing safety in all operational scenarios.

Streamlined Automation:

The Whiting PLC Safety System introduces a new era of operational convenience through advanced automation features:

- Auto level: Achieves precise leveling effortlessly.

- Auto lower: Facilitates controlled descent for optimal safety.

- Auto dog: Engages the safety dog automatically, adding an extra layer of security to your lifting process.

User-Friendly Interface:

The touch screen control panel with self-diagnostics provides operators with an intuitive interface. Easily monitor system status, diagnose issues promptly, and manage operations efficiently—all in a user-friendly manner.

Technological Advancements:

- Proximity Switches:

- Replaces conventional mechanical limit switches with advanced proximity switches, contributing to a more reliable and responsive system.

- Wireless Pendant:

- Enhances operational flexibility by replacing the under-floor push-button station with a wireless pendant, allowing operators to control the system from a distance.

- Overhead Voice Messaging System:

- Announces car movement overhead, fostering enhanced communication and situational awareness.

Comprehensive Management:

- Alarm Management and Track Usage:

- Effectively manages alarms and provides detailed tracking of system usage, facilitating comprehensive monitoring and analysis.

Remote Support:

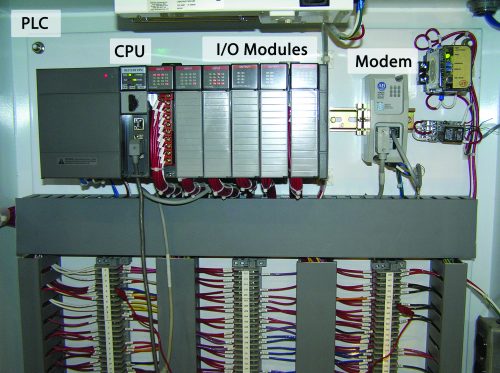

- Remote Modem Access for Online Factory Support:

- Enables seamless remote access for online factory support, ensuring swift resolution of any potential issues and minimizing downtime.

Elevate your lifting operations with confidence, backed by the unmatched safety and technological prowess of the Whiting PLC Safety System. It’s not just an upgrade; it’s a commitment to excellence in every lift.

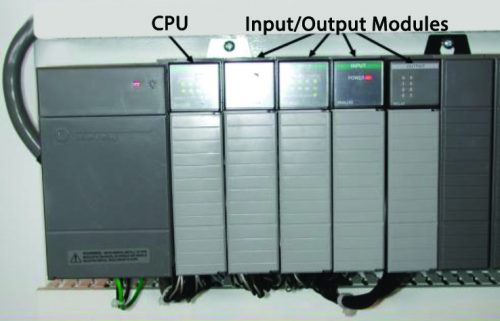

PLC Controller

- Microprocessor-based

- CPU (Central Processing Unit)

- Modular Design

- Digital/Analog Input Modules

- Digital/Analog Output Modules

- Programmable

- Remote Access

- Replaces Relay System