Railcar Retarder System

Whiting’s Rail Retarder System plays a pivotal role in the precise positioning of railcars within spot repair systems, ensuring efficient and controlled movement during maintenance operations. These retarders, integral to the railcar handling systems, are operated seamlessly from a central control panel, offering a centralized and user-friendly interface for operators.

Our hydraulic retarders are equipped with three distinct positions: spot, open, and closed. This versatility allows for tailored control over the railcar’s movement, facilitating optimal positioning for repair or maintenance tasks. The spot position is particularly crucial for accurately aligning railcars within the designated repair area.

Precise Controls Provide Safety and Efficiency

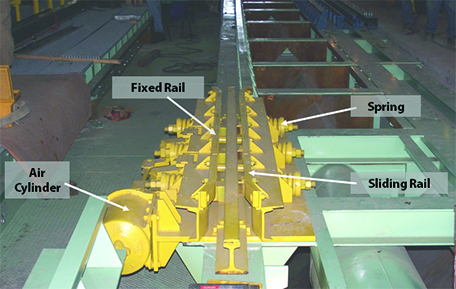

The use of advanced electronic control technology sets Whiting’s Railcar Retarders apart. The pneumatic retarders are electronically controlled, enhancing precision and responsiveness in their operation. This electronic control ensures a high degree of accuracy in stopping and positioning railcars during the spot repair process.

Key to the effectiveness of the Whiting Rail Retarder System is its impressive spotting distance of 11 feet. This capability allows for a considerable margin of adjustment, accommodating various railcar sizes and configurations. The system’s adaptability is a significant advantage in handling diverse railcar types within the maintenance facility.

Additionally, the Rail Retarder System is designed to develop a substantial stopping force of 7,000 lbs. per foot. This robust force is essential for safely and efficiently bringing railcars to a controlled stop, contributing to the overall safety and precision of the railcar handling process.

The pneumatic nature of the retarders further enhances their reliability and efficiency. Pneumatic systems are known for their rapid response times and durability, ensuring that the Rail Retarder System can meet the demands of high-frequency railcar movements in industrial settings.

Integrating the Rail Retarder System into Whiting’s overall railcar handling solutions enhances the comprehensive capabilities of their offerings. The synergy between retarders and other components, such as railcar movers and pullers, ensures a synchronized and efficient workflow in railcar maintenance and repair operations.

In summary, Whiting’s Rail Retarder System stands as a technologically advanced and reliable solution for accurately positioning railcars during spot repair operations. With electronic control, substantial stopping force, and an impressive spotting distance, this system contributes significantly to the efficiency, safety, and precision of railcar handling within industrial facilities.

Rail Retarders Applications

Rail retarders, including hydraulic retarders, play a significant role in various railway industry applications. Here are key areas where they are typically used:

Railway Yards and Hump Operations: Whiting rail retarders are widely used in railway yards and hump operations for controlling the speed and movement of railcars during classification and sorting processes. They enable precise positioning and prevent excessive impact forces, thereby ensuring the safety of personnel and equipment.

Freight Train Braking Systems: An integral component of freight train braking systems, rail retarders help efficiently slow and stop heavy freight trains. By providing controlled braking force, they contribute to smoother deceleration, reducing wear on the train’s braking system and enhancing overall safety.

Maintenance and Safety Considerations: Our railcar retarders allow for precise slowing or stopping of railcars, mitigating damage to infrastructure and railcars. They can also contribute to cost savings and maintenance optimization by minimizing wear and tear on the railcars’ braking systems, therefore extending equipment lifespan and reducing maintenance costs.

At Whiting Corporation, our top-quality and reliable rail retarder systems are designed to boost operational efficiency and safety. Contact us today to learn more about our rail retarder solutions.